Eco Materials Group (Eco)

0 € (0%)

of 250 € goal funded

500 € minimum investment

Quick Pitch

We can offer an unique HI-TECH product with unprecedented and unbeatable performance in the wood chip market. It nables the recycling of wood waste into clean, analysed and logged wood chips ready to be incorporated into our customers' products in line with their strict purity requirements.

Investors are offered an investment in a fast growing venture aligned with strong growing demands worldwide for clean wood chips from wood waste utilised for particle boards, wooden fiber insulations, food ration packages, clean pellets and other applicable products.

There is a huge market potential in EU and worldwide. For particle boards the global supply is currently

73M m3/ year (2021) with growing demands.

One multinational industry major utilising particle boards in their products has stated they are committed shifting to 80% recycled wood by year 2030. And the other giants of the industry we are in dialog with tell they have similar intentions.

Why not be part of this fantastic growth journey. We can offer the Fundwise investor shares with solid investment returns and participation in dividend pay-outs.

Problem & Solution

Opportunity

There is a huge market for clean wood chips recycled from wood waste that can go straight into new products.

This is without the need for today's wood chip cleaning solutions with low volume throughput and/ or leaving high levels of contamination. Using vigin wood as the source for the wood chips, it consumes high amounts of energy to dry the high moisture content. And chopping down forests releases CO2 that is bound in the trees into the atmosphere.

Problem

Today’s markets cannot deliver clean wood chips to requested volumes.

Wood waste is today commonly delivered to plants burning it for heat and energy. Still some places uses it for land-filling but to a lesser and lesser degree. Only minor parts of wood waste amounts are recycled. And what is recycled intended for new products is almost without exception contaminated to a far too high degree to be of practical use, which several major companies in the industry have confirmed. The contamination means physical damage to working tools and the inclusion of toxins in new products.

Particle board makers use costly investments to refine contaminated wood chips purchased in the market and regretfully with less than satisfactory results both with regards to cleanliness and volume throughput.

The use of virgin wood has a high moisture content around 50% requiring drying which wastes high amounts of energy and increases the CO2 output into the atmosphere. The felling of trees further releases CO2 bound in them into the atmosphere.

Solution

1 - ECO’s unique HI-TECH units are truly market leading. Contaminants are easily removed and reduced to an unprecedented and exceptionally clean level maintaining a high volume throughput.

2 - ECO’s unique HI-TECH units measures and logs the woodchips continuously which data can be shared with customers for customer assurance of wood chip purity levels received. This supports customer satisfaction and peace of mind.

Eco contributes to a sustainable circular economy and a clean environment.

Product/Service Details

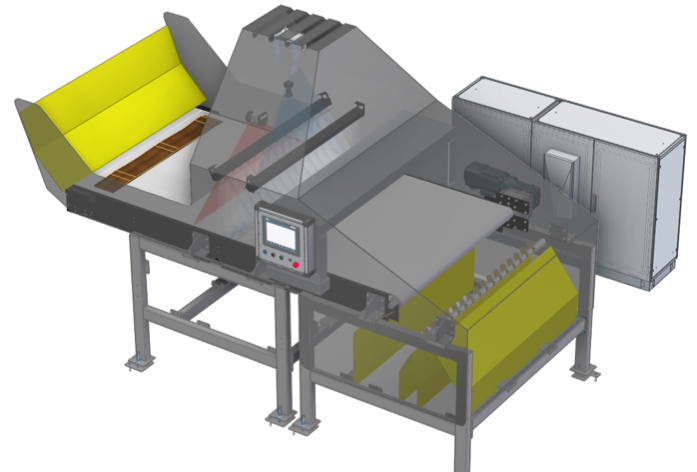

• The HI-TECH units enables an effective reduction of contaminants in the woodchips with high throughput volumes down to purification levels exceeding major companies requirements

• The HI-TECH units effectively and continuously measures and logs the quality of woodchips which data may be shared with customers for assurance of the high level of quality delivered to support customer satisfaction and peace of mind concerning their products sold in the markets

• Technical key-points:

- Double-scanning

- AI-analysis

- Precise separation system

- Volume capacity 25 ton/ hour

- Operational between -20 to +40 deg C

• ECO offers various options for purchase or cooperation:

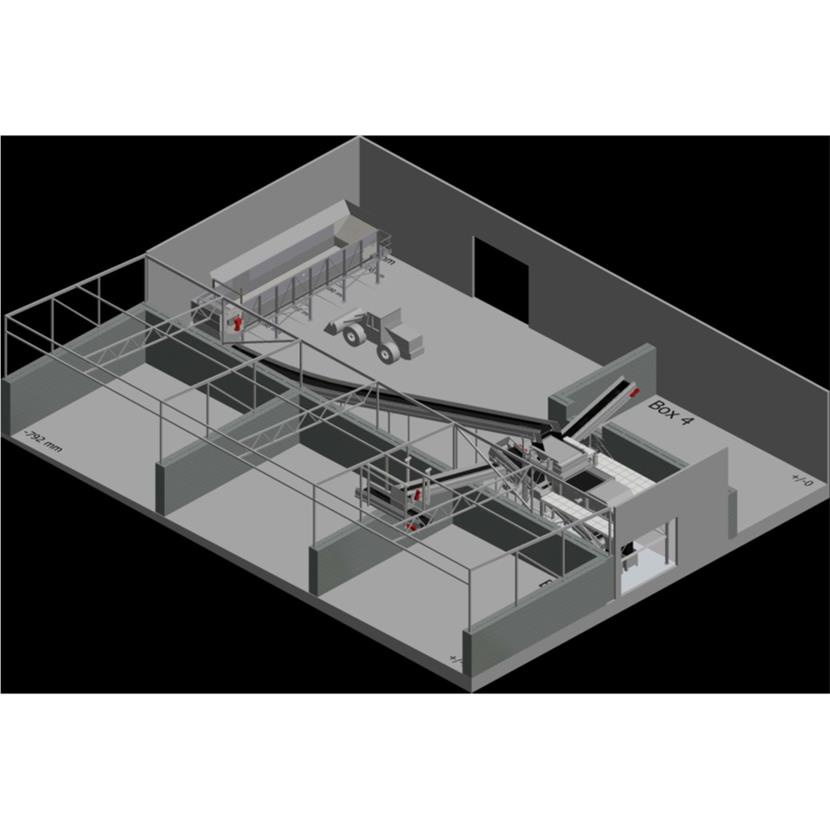

i) Whole wood chip recycling facilities with the unique HI-TECH units fully integrated - ‘royalties’ on produced volumes

ii) HI-TECH units sold separately - ‘royalties’ on produced volumes

iii) Purified and documented wood chips to customers from co-owned woodchip recycling facilities

There is also installation, maintenance and training support offered.

Business model

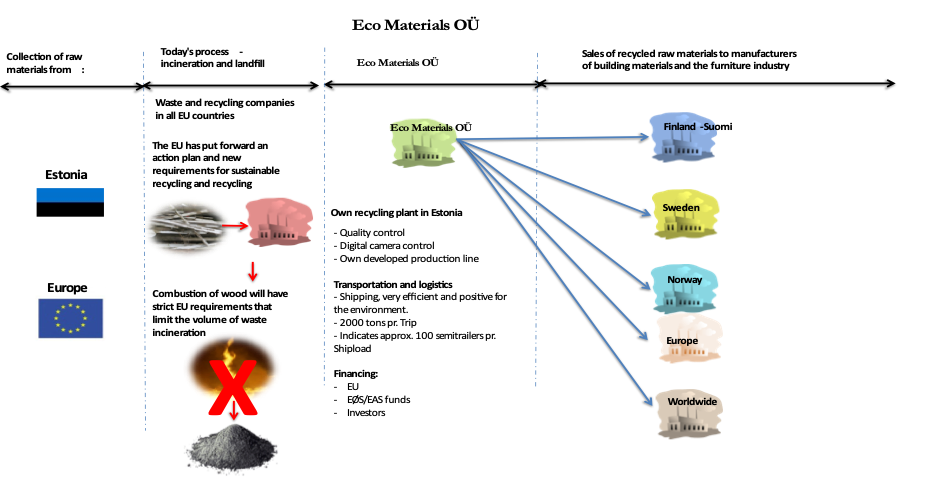

Initial business model, see image

Market

The focus is on the markets in Europe (EU) with the highest wood waste flow for recycling. Germany, UK, Italy, France. But also countries with 'special opportunities' and the countries in the nearer geography. Furthermore, the demand for recycled wood based products is huge worldwide where we take aim in the longer context.

Traction & Accomplishments

• Agreement signed with one major company in the Nordic region and discussion ongoing concerning installation of HI-TECH units with a complete recycling facility

• Eco owns the IP and agreement signed with supplier of technology

• A regional investment company is ready to take a co-investor role today on identifying a suitable lead

• Eco is in progress with several of the largest customers in EU purchasing wood chips and in registering process as supplier with the largest wood chip buying client in EU

• Eco has letter of intent (LOI) with strategic suppliers of wood waste

• Eco is in process with a worldwide renowned certification body for Eco's products

• Eco Materials AS (Norway) is producing wood chips from wood waste in Norway in partnership with one of Norway’s largest waste recycling companies

• Eco Materials AS (Norway) is already selling wood chips to customers in Scandinavia

How We’re Different

We have an unique technology performing above any gear available in the current market with regards to volume throughput and cleanliness of wood chips out... and this while facing a huge and growing market for documented clean recycled wood chips from waste wood.

Uses of Funds & Timeline

The investment funds will be used to complete the construction of the 2 first HI-TECH units.

Timeline to complete and install the 2 first units is by end Q4 2022.

Obligations to Investors, Profit Distribution

Investors are offered an investment and shares in a fast growing venture aligned with strong growing demands worldwide for clean wood chips from wood waste. Both solid investment returns and participation in dividend pay-outs is offered.

Company is valued to € xx 000 000 based on 5-year financial forecast and EBITDA multiples. Public round size €250 000 - €1 000 000 (y% - yy% of Eco shares). The €1 000 000 investment is in completing the hardware i.e. the first 2 HI-TECH units and 1/3 is to cover overhead costs for this year.

The minimum investment ticket is €500 and maximum €1 000 000.

Risks and Mitigation

Eco owns the IP and looking to initiate patent applications.

Eco is in process writing supplier agreements with largest customers in the EU market.

Eco is looking to source and storage long lead time items.

Eco is working in accordance with business plan and marketing plan but will take an opportunistic approach if and when possible and in order to mitigate risks.

Eco has LOIs with strategical suppliers of raw materials for the reference plant planned to be erected in Estonia.