Vaat Brewery

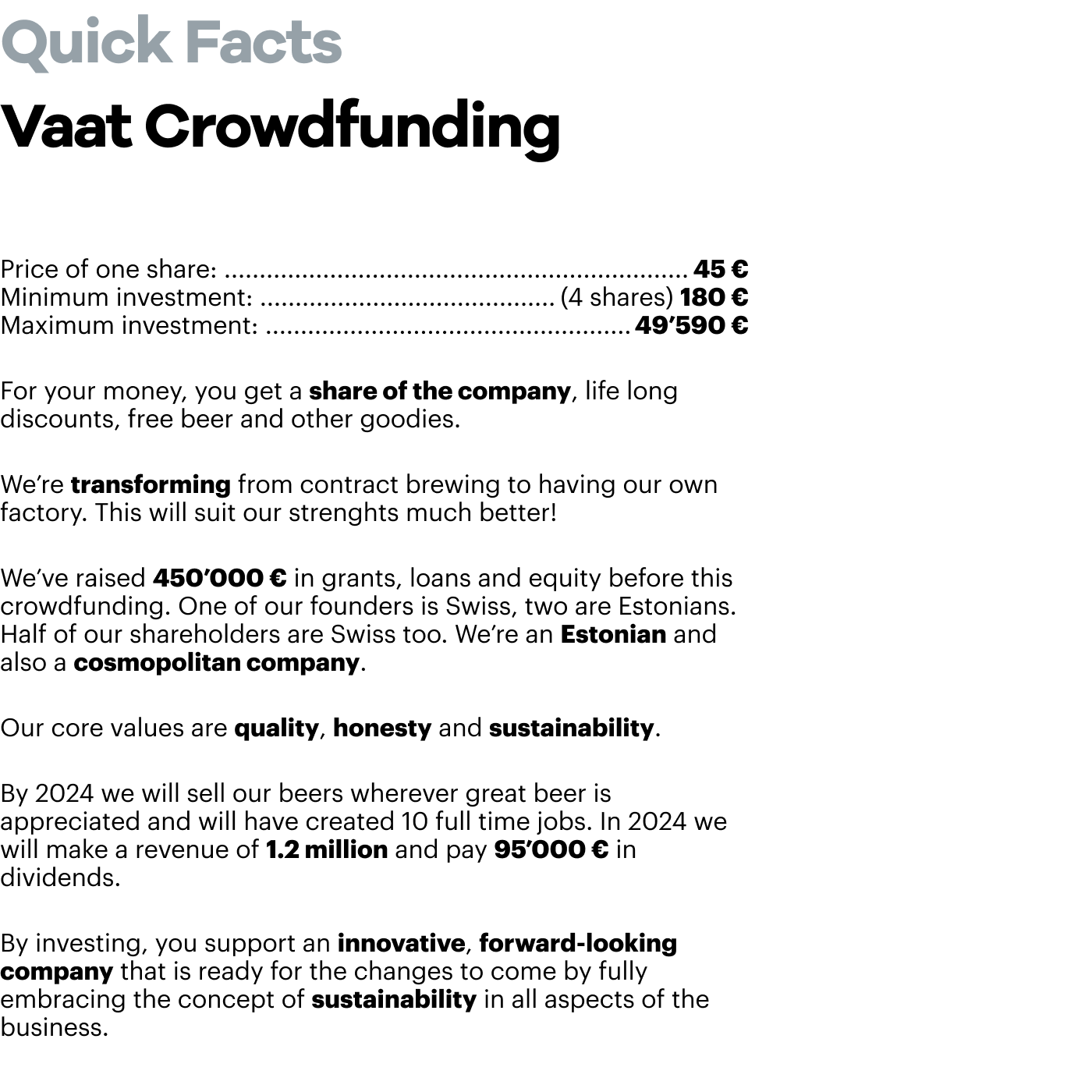

210 105 € (210%)

of 99 990 - 214 965 € goal funded

180 € minimum investment

Quick Pitch

We are Vaat and we are building the most innovative, forward looking and sustainable brewery you can imagine!

Our VISION is a place of great fresh beers, low- and non-alcoholic alternatives and other interesting drinks. A place where beer lovers from around the world meet to witness the latest innovation in ecologically sustainable, high-quality micro brewing.

We are building a modern production brewery and a tap room in Tallinn, Estonia. We've raised about 75% of the funds for this project so far.

But we need YOU to get us over the finish line!

#vaatbrewery #DoYourOwnThing #innovation #revolution #greenTech #beTheChangeYouWantToSee #businessAsAForceForGood

Questions? Leave them under the tab Discussion (Estonian, English, German or Swiss German) or write to Markus mh@vaat.ee.

Update (11th November): If you haven't tried our beers yet, here's what you can do depending on where you are:

- Tallinn: you can get a free bottle of Witty Nelson, IPK, and Jailhouse Brew each from Koht, with the code word 'revolution'.

- Tartu: you can get a free bottle of Witty Nelson, IPK, and Jailhouse Brew each from Barlova, with the code word 'revolution'.

- Switzerland or any other place, write to mh@vaat.ee and we'll do our best to sort you out.

Important notice: This is an equity based Crowdfunding, investing means buying a part of Vaat! And you can do that no matter where you're from! We removed all legal and logistic hurdles for you to be able to easily invest without the need for a share portfolio or bank account in Estonia. Just be aware that in case you want to actively participate in the decision making/voting of the company and you are not an Estonian resident, you may one day need some way of digitally signing documents (not a hard problem to solve). An Estonian e-residency is not required for that but can be a fun thing to have in any case.

Problem & Solution

Let's talk about opportunities. Over the time we existed as a brewery outsourcing our main production, different experiences taught us a few valuable lessons that helped us understand what we really wanted to do and what kind of company we needed to be in order to be successful.

The Opportunity of Independence

One thing we learned was that contracting doesn’t play to our strengths. One of our core skills is brewing itself and the technology of brewing which means we need control over these processes. This will give us the creative freedom that we loved on our pico system, but at scale.

It also means more flexibility regarding production scheduling, volumes, the ability to plan, minimise storage, and the ability to react to short-term market and customer demands.

The Opportunity of Tech Innovation

We strongly believe that the craft brewing ecosystem is in need of technical innovation. Some of the cutting-edge technologies of big producers can be leveraged by micro-breweries, yet very few do. By breaking traditional industry limitations, we will be able to produce a much broader array of beverages in a more cost-effective way.

We will also be able to grow our capacity without buying a larger brewhouse meaning a much lower investment need for expansion compared to other breweries.

The low/non-alcohol Opportunity

This is the (craft) beer segment with the largest projected growth by far.

Late millennials and younger generations drink less than any generation before them. Arab countries are removing their restrictions by allowing non-alcoholic beer. People generally become more health conscious and start preferring drinks with less alcohol. The offering on the other hand is still limited.

We want to innovate as this is not just the segment with the largest projected growth but also the segment with the biggest need for innovation. Mainly regarding the question of how to make non/low-alcohol beers as full-bodied and tasty as their higher-alcohol counterparts.

Providing great non-alcoholic and low-alcohol alternatives leads to health benefits for consumers. With countries raising their excise tax on alcohol, this is also the segment where prices can be held competitive without giving up on margins.

The Green Opportunity

All industries have to become more sustainable and we have laid out a plan of how this can be achieved in brewing. Apart from being a necessity in face of the worsening climate crisis - and because of that - it is also a way to attract consumers to our brand and show them that by choosing us over the competition they can lower their own ecological footprint.

Becoming the most ecologically sustainable brewery in Estonia and beyond will give us the possibility to be a role model in a time of change.

Vaat as Opportunity for Estonia

Bringing our main production back to Estonia and growing here will have a number of effects beneficial to the Estonian economy as well as the Estonian public.

As one of the top rated Estonian breweries we will finally also be able to say that all our products are of Estonian origin and that we are creating all our added value locally.

As a production brewery with tap room in Estonia we will help create jobs directly as well as in adjacent industries. We'll directly create 5-10 jobs during the period of this plan, later more. The craft beer industry is a great job creator as the artisanal aspect of craft brewing means a relatively low level of automation.

Estonia is committed to reach climate neutrality by 2050. By building a practically 0 emission production facility in 2020 we can be an inspiration and example even beyond our own industry.

We will be able to have a bigger impact on and contribution to the growing reputation of Estonia as one of Europe’s top craft beer destinations. With Põhjala, Pühaste, Tanker and others in the lead, we will contribute to a staggering amount of world class quality craft beer coming out of this little but innovative and industrious country.

Estonian consumers will profit from lower prices, fresher products and a much reduced ecological footprint of the beer they consume.

Image: our new location after completing renovations, ready to recieve the equipment.

Product/Service Details

Our products are characterised by balance, cleanness, and drinkability. We also want every brew to have its own unique feature that makes it stand apart from products of the same style.

Once we can start production in Telliskivi, we will back-source production of our current range (see details in full business plan) and lower the prices to a more competitive level.

We will produce a wide range of beers as well as non-beer beverages such as seltzers, kvass or kombucha.

Our core focus will be on a wider range of low-alcohol and non- alcoholic beers while aiming to set new benchmarks when it comes to the flavour and complexity of low-alcohol brews. We will vary our selection frequently, often releasing several new beers at the same time or in short succession.

Variation brews

Something we will be able to do thanks to our unique setup are parallel variations of drinks. For example 4 IPAs with the same base that are brewed at the same time but are each dry-hopped with a different hop-variety. Such variation brews can be sold as single products or as packs of multiple variations, something the craft beer crowd appreciates.

Pricing Strategy

Our pricing strategy is primarily competition-based. According to consumers and our own goals and expectations, we are one of the top Estonian craft breweries. Our prices will be closely benchmarked against the market price leaders like Põhjala, Pühaste or Tanker.

Premium pricing

In addition we plan to release a smaller number of products in champagne bottles with a premium pricing scheme. An example for such a product is our birch-sap, rice and sake yeast based San of a Birch (pilot brew), which is a suitable wine replacement for fine dining establishments.

Our current products

Business model

Location & Facilities

Vaat will operate on a 280m2 industrial space in one of Tallinn's historic factory districts close to Tallinn's railway station. The location is in Telliskivi’s hall M (M-hoone) in very close proximity to the Telliskivi creative city, which is one of Tallinn's most busy bar, restaurant and entertainment areas that attracts locals and tourists alike.

The space allows us to build a small tap room that can accommodate about 30 people (sitting) and allows the brewery to cope with expansion for at least until 2024 according to our growth plan.

Tap Room

Our tap room will attract the craft beer crowd with a high-quality and frequently varying selection of beer. With its very central location in Telliskivi, one of the major nightlife areas of Tallinn, it will also attract a decent number of walk-in customers just looking for the next drink.

Being able to directly sell your product to the consumer is a huge advantage, especially in the beverage industry, where there can often be 2-3 intermediaries taking their own cut.

We are expecting the tap room to provide at least 100'000 EUR in revenue per year, which initially is 40% of the revenue.

Staffing

Until 2024 our head count is expected to grow to about 10 full time equivalents, that means work for 10-15 people. Please see the staffing chapter in our business plan (documents) for more information.

Target B2B Markets

From 2021 we will be offering our new beers to our existing customers in Estonia, Switzerland, The Netherlands, Latvia and Finland which can cover the expected B2B turnover if the channels/leads are curated during the building period. At the same time, with fresh samples of our new products we can pick up the sales work again and follow up on many of the leads we had to put on ice due to the lack of production and pricing flexibility.

Goals for 2020 to 2024: Getting a couple of products into one of the Estonian supermarket chains (e.g. Selver, Prisma, Rimi). Intensifying export to Finland including Alko (monopoly) tenders and Switzerland, getting back to the Russian market and adding Sweden (low alcohol beers as well as the Swedish monopoly Systembolaget), Germany (lighter beers), Austria, Italy, France, Spain (especially Barcelona), Poland, Croatia, Slovenia, Canada, USA, Brazil, China, Japan, South Korea. These are all countries where we already have established connections and/or countries with good and established craft beer markets. The list is not exclusive, in the end we want to be represented wherever great craft beer is drunk.

Revenue target: Starting with a cautious revenue target of ~170'000 EUR for the non-taproom sales, of which 50-70% is export. We then continuously grow this revenue to ~1'000'000 EUR in 2024. Looking at our competition power regarding pricing and comparing to similar players in the market, these are achievable goals.

Additionally, we're working on an online fulfillment pipeline, read more about that at the bottom in the Risk chapter.

Technology & GreenTech

The planned Vaat brewing system is revolutionary. It will not only enable us to produce drinks of highest quality in a cost-effective way. At the same time we are building the greenest brewery in Estonia, significantly reducing the usage of CO2, water, energy, and chemical detergents.

Production capacity

Volume explanation: 1 HL = 100 litres = 227 x 0.44l cans.

With the initial number of 10 brewing vessels, we will be able to produce 2000 HL of beer per year or up to 6000 HL of a mix of products including Seltzer and soft drinks. With the additional 8 brewing vessels the room plan foresees, we could theoretically reach a yearly production of 10000 HL.

According to our growth plan, the production volume of our first year will be 600 HL and then gradually increase to 2800 HL until 2024.

The Vaat brewing setup

We will be using a brewing vessel that will replace many of the vessels that are traditionally used. That means instead of purchasing a traditional system with a mash tun, a lauter tun, a brew kettle and fermentation vessels we can brew and ferment our beers in one and the same multi-purpose tank. In conjunction with the other parts of the system this has a series of advantages:

-

Quality: A closed process from start to finish combined with using Nitrogen instead of CO2 allows for better control of the processing environment.

-

Flexibility: Simultaneously ongoing brewing processes are possible.

-

Efficiency: Homogenised fine-mashing and extraction processes allow optimised usage of raw materials.

-

Time savings: Less equipment to maintain in comparison with traditional multi-vessel setup.

-

Compliance: Easier due to simpler and more sanitary processes.

-

Space savings: Less vessels to maintain (in comparison to the traditional MT/LT/BK/FV setup).

-

Quality & Cost efficiency: Water deaeration helps to mitigate oxidation risks and prolongs equipment lifetime.

Sustainable, non-polluting & CO2 free brewing

As part of our plan to greatly reduce our environmental impact, we have decided to work without the use of additional CO2, reduce water usage, reduce chemical usage, and use recuperated heat from the brewing process to heat the hot water tank.

Fermentation produces vast amounts of CO2 which breweries vent off into the atmosphere only to then use new CO2 to carbonate their beer in bright tanks. We are going to use the naturally produced CO2 of the fermentation to carbonate our products at the end of the brewing process without using any additional CO2.

CO2 is used by breweries in large quantities during the brewing process, e.g. to purge air out of tanks and hoses. We are going to completely replace this CO2 with Nitrogen, which is not a greenhouse gas, but in fact composes 78% of the air we breath.

We are also going to use ozonised water instead of chemicals for sanitisation. Ozone is the most efficient disinfection agent available and replaces traditional chemicals. It offers at least 20 times higher microbial inactivation potential which means that both concentration and disinfection time can be significantly reduced

It is also very gentle on materials and therefore prolongs equipment lifetime. Ozone is produced on demand and utilises oxygen as its only raw material. After use it quickly decomposes into oxygen, leaving no byproducts. As ozone is not stored, storage needs are reduced.

The use of ozone also significantly reduces water needs during the sanitisation process.

Clean steam heating

Heating with clean steam has many advantages and is used frequently in the food industry while not yet so much in brewing. Clean steam heating is sustainable and efficient, it allows for uniform product heating without scorching.

Packaging: Cans and champagne bottles

A lot of craft breweries world wide including leading Estonian breweries have already pointed it out, canning is quickly becoming the new standard in craft beer packaging for many good reasons. It increases product quality, protects the environment, increases the usability of the product and decreases the need for space.

Vaat is going to use 44cl cans for most products instead of the traditional 33cl glass bottle. Additionally we are going to package some special releases in larger champagne bottles.

Centrifuge (also called separator)

When a beer is ready, you can either wait for all the organic particles that you don't want in your end product to settle down or you can run the beer through a device that uses centrifugal force to separate these particles from the liquid. The advantages of using a separator are higher quality, time efficiency, brewing efficiency and flexibility.

Fine grind wet milling

Most breweries and almost all craft breweries use traditional dry mills to turn their raw materials, mostly malt, into grist. We've tested and integrated wet milling which fits perfectly into our highly efficient, low-oxygen brewing setup and has many advantages over traditional milling such as better brewing efficiency, more flexibility, and higher product quality.

If you're interested in further details regarding the technology, please read the Technology chapter in our full business plan.

Market

Market Overview

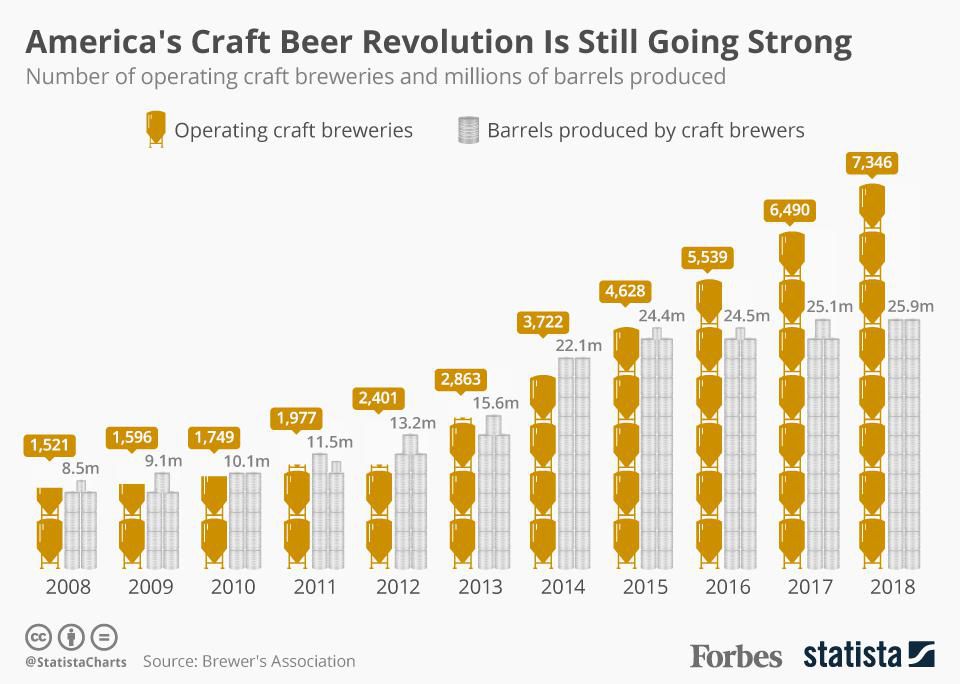

In 2018 the world consumed about 188 billion litres of beer. (For Estonians: That’s about 8 Ülemiste lakes).

This number is only growing slowly, but what’s still changing dramatically is the craft beer market share. Almost everywhere in the world, the number of craft breweries and the productions volumes are increasing every year. In the US, where the Craft Beer Revolution started earliest, there is still no end of the trend in sight (see image below, 2019 numbers not available yet). In fact craft beer is not a boom anymore but has established itself as the 'new premium' as Johnny Forsyth, Associate Director of Mintel Food & Drink puts it.

The surge in demand for more beer styles coupled with increase in per capita income among the target customers keeps pushing demand for craft beer in the key regions. Every year, craft beer volumes increase on every continent, although the USA and Europe are still the drivers. The results of a Mintel study on new craft beer products in 2018 suggest that Europe is now more innovative in this area than the USA.

While the overall beer consumption in Europe has been ever so slightly decreasing, the craft beer market is growing at a steady pace. In Estonia craft beer still accounts for only about 3% of the total beer revenue and this is not the lowest number in Europe while in certain US states, craft beer makes about 25% of the total beer market revenue. This shows the large growth potential European craft beer still has.

The forecast regarding our focus on non- and low-alcohol beers is even more promising. There is a shift toward non-alcoholic and light beers. For 2018, Plato Logic reports global consumption of 43.96 million hl in this segment. This is up from 40 million hl in 2016. Europe leads the field with 27.22 million hl. According to The Brewers of Europe, the international Reputation Institute performed a survey of more than 10'000 adult Europeans in twelve countries in 2018. This showed that moderate alcohol consumption was a factor in the lifestyle or drinking culture of almost 50% of those surveyed, and that they appreciated innovative, reduced-alcohol and non-alcoholic products.

Market Trends

Brewing only beer is a thing of the past. These days breweries fill their cans, kegs and taproom taps with excellent beer alongside bubbly hard seltzers, nitro cold brewed coffee, fruity kombucha as well as a few non-alcoholic or low-alc options.

Low-alc beer

As highlighted throughout our business plan one important current trend that we appreciate is the trend towards lower alcohol alternatives in a range between 2% and 4% alcohol.

Non-alcoholic beer

For the same reasons the demand for non-alcoholic beer is increasing as well. Additionally some of the more progressive muslim countries are changing their laws to allow for such beverages.

Soft-drinks

Fermentation is not limited to beer and brewing doesn’t need to include fermentation. There is a large array of possibilities for a brewery with the type of flexible system we are building. We can and will brew other fermented drinks like kvass or ginger ale, as well as brewed (but not fermented) soft-drinks like malt drinks to add variety to the tap room list.

Hard & Soft Seltzers

Craft breweries with modern equipment are perfectly set up to enrich their offering with seltzers, spiked or not, hop-flavoured, fruit-flavoured or plain, they can be a great and low-calorie addition to an interesting tap list that contains something for everyone.

The IPA is not dying

The IPA style has become the most popular craft beer style and the IPA isn't going anywhere anytime soon. Fresh hoppy beers, especially in the low alcohol segment can always be sold and sell fast.

More information

For a customer analysis as well as a competition analysis, please see the Business Plan under Documents. If you're looking for market share numbers, you won't find any. At this stage the market share is not an important indicator for us, our sales goals and our vision will guide us to appropriate growth.

Traction & Accomplishments

Our Story

Drawn into the spell of the European craft beer revolution in the early years of this millennium we found that the best way to get the beer we really wanted to drink was to make it ourselves. The brewing adventure always begins with a love for beer, the realisation that mass-produced lager isn’t the only type of beer, and the fascinating discovery of the world of beer styles. It was the same for us. Our fate was sealed when Co-Founder Oliver brought a bottle of Punk IPA to a party. It was also Oliver’s kitchen, where the first pilot batch of Vaat was brewed.

Vaat was registered as a company in 2013, our first product, Jailhouse Brew, was released in 2015. We started out developing recipes at our pilot brewery in Tallinn in our spare time.

With great care for quality and detail we brewed and improved a series of recipes while looking for a suitable place to brew them at scale. In 2015, we got the rare opportunity to start producing our beers at the world's most renowned contract brewery, the Proefbrouwerij in Belgium.

We were thrilled. To be able to produce our beers in a high quality brewery without the risk of having to build a larger factory was exactly what we had envisioned.

Our Achievements

We quickly established ourselves among the top 5 rated breweries in Estonia according to Untappd and have been ranked between the 3rd and 6th place ever since.

Since the start of our adventure we have released 7 beers as well as 3 collaboration brews.

Our beers are available in craft beer bars, shops and restaurants in Estonia and we have exported to Switzerland, Finland, The Netherlands, Russia, Latvia and Lithuania.

Between 2015 and 2018, despite disadvantages in pricing and setbacks regarding the brewing side, we generated a revenue of over 250’000 EUR - all in our spare time while working full time on our day jobs.

Witty Nelson has been featured as beer of the month at Drinks of the World in Switzerland in May 2017 and made it into 220 outlets of Coop Switzerland in 2018.

Swiss Gault Millau star chef Nenad Mlinarevic is a fan of our IPK and served it in his pop-up restaurant project in Zürich.

Jailhouse Brew has won a Gold medal at the Frankfurt International Beer Trophy in 2018.

In 2019 and 2020 we submitted a successful PRIA grant application, raised further 300'000 EUR funding, wrote a detailed business plan, survived the bankruptcy of our Swiss importer, found a new Swiss importer, found and renovated our new venue and engeneered large parts of our brewing system while surviving Covid-19.

How We’re Different

Sustainability

We believe in sustainability as a greater concept. We want to be a force for good as a business. We believe...

- That we must be the change we seek in the world.

- That all business ought to be conducted as if people and place mattered.

- That, through their products, practices, and profits, businesses should aspire to do no harm and benefit all.

- To do so requires that we act with the understanding that we are each dependent upon another and thus responsible for each other and future generations.

Technological Edge

As described throughout our business plan, our brewing system will provide us with a technical edge that lets us produce high-quality craft beer in a cost-effective way, give us high flexibility in production planning as well as product design and lets us produce other types of drinks as easily as beer.

Greenest Estonian Brewery

We will provide value to our brand, our community and our planet by being the brewery with by far the lowest carbon footprint in Estonia and beyond.

Focus on making no/low alcohol beers more interesting

By focusing on a broad range of interesting low alcohol beers we will be able to compete in the fastest growing segment of the (craft) beer market and provide healthier alternatives for craft beer drinkers everywhere.

Quality

Great beer is hard to make and by far not every brewery can or wants to reach the pinnacle of craft. Worldwide there are 100 to 150 breweries that create beer on a quality level we're targeting. Quality of execution is already one of our strengths.

The Tap Room

Tap Rooms are gaining popularity but by far not all breweries have one. Our centrally located Tap Room in Tallinn will give us a competitive advantage over breweries without one.

Furthermore...

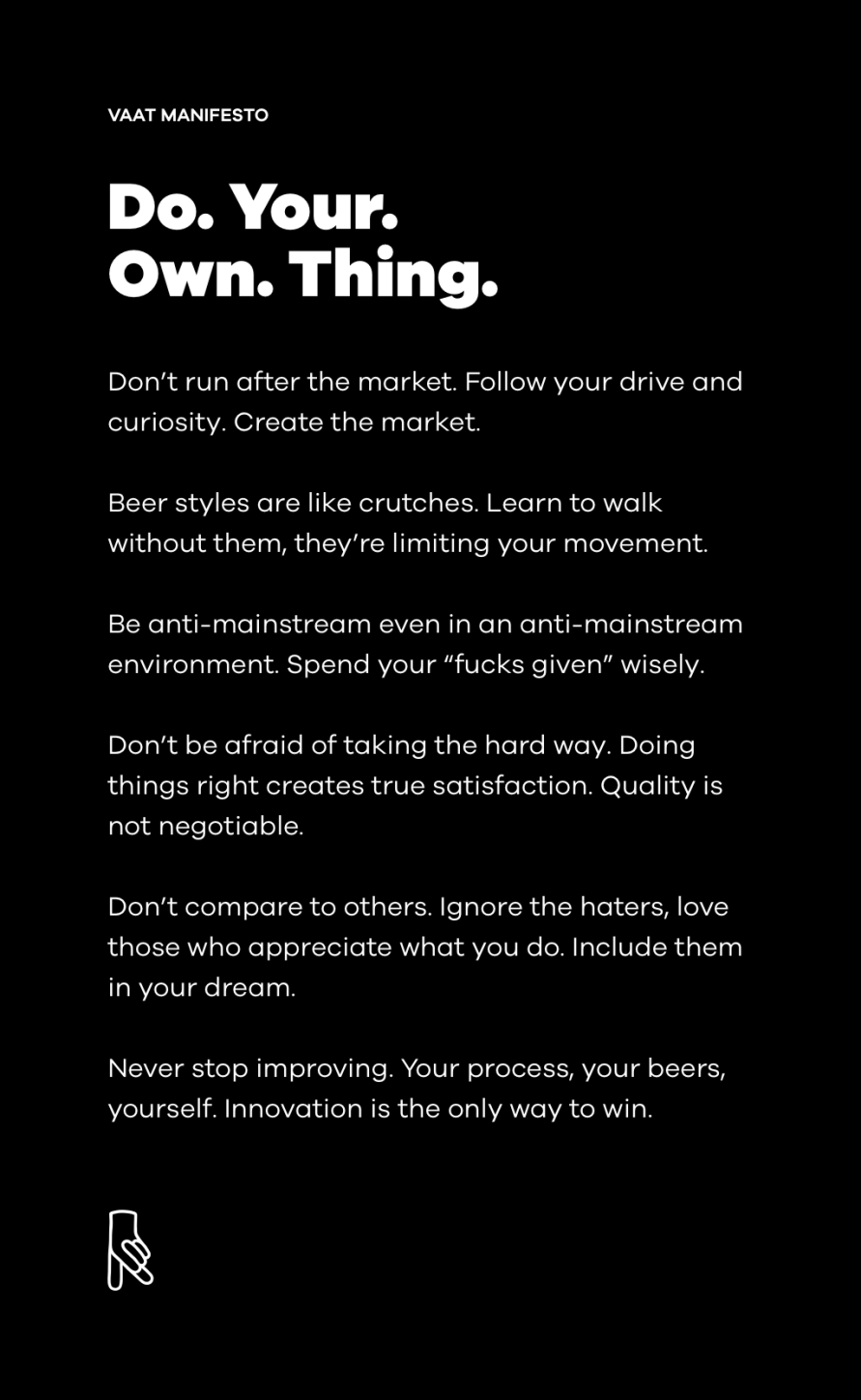

... we will keep using and developing our unique, high-quality brand/design and will preserve our nerdy, innovative, friendly, cosmopolitan, daring, non-conforming mindset.

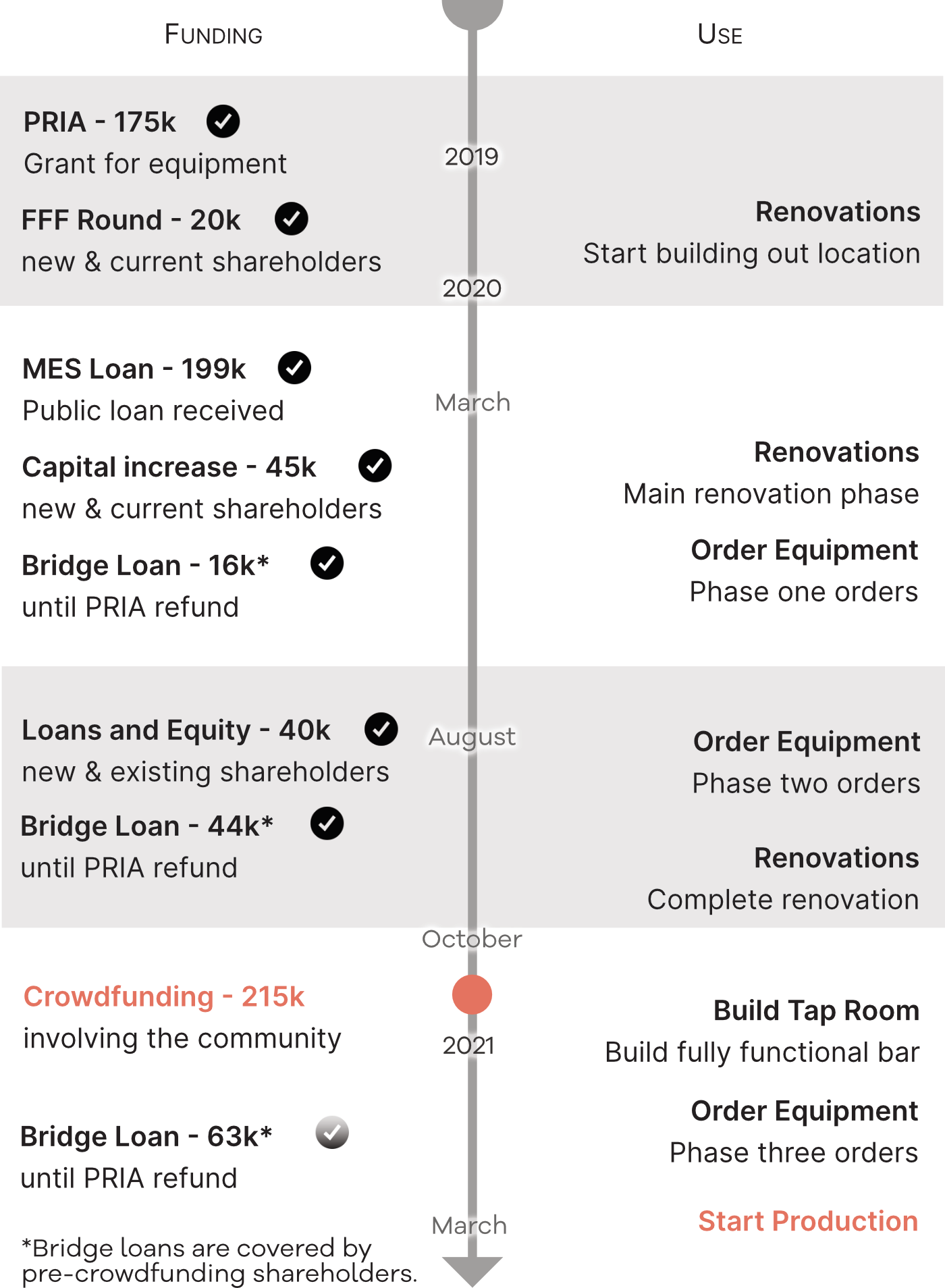

Uses of Funds & Timeline

This crowdfunding is only one part of a larger funding plan for our project. For our plan to succeed, we need at least 640'000 EUR. We're at 75% of that before this Crowdfunding campaign. We're really happy with this progress, but we really need you to get us over the finish line.

Sources of Funds

PRIA Grant (175k) ✔️

In 2019 we successfully applied to PRIA for a grant that supports businesses in the Agricultural sector. PRIA, the Estonian Agricultural Registers and Information Board, is a government agency under the Estonian Ministry of Rural Affairs. Vaat applied for equipment with a value of ~450'000 EUR and was awarded a 39% coverage of this investment, which is 175'000 EUR. This support is an EU grant, not a loan, meaning it will not have to be paid back.

MES Loan (199k) ✔️

In addition the support from the PRIA grant, we applied for a loan from the Rural Development Foundation (MES), a foundation established by the Republic of Estonia. As a public loan instrument, MES has offered us very favourable conditions such as a 2 year grace period and an interest rate of only 4%, later lowered to 2% for the first two years thanks to Corona measures. In the beginning of March we got a positive decision from MES.

Private Equity and Internal Loans (90k + 12k) ✔️

Not all needed investments and build-up costs are covered by PRIA, the scope of the MES loan or any other instrument. Until September 2020 we raised 90’000 EUR in equity to start the purchasing phase on a solid basis regarding own capital. We also got 12'000 EUR of loans by current shareholders.

THIS Crowdfunding (215k)

This is where we stand now. Your contribution matters!

Use of funds

With the funds raised during this campaign, we will finance or co-finance (with PRIA grant) the following things.

Absolutely essential (~145'000 EUR)

- building and furnishing of the taproom

- canning line (39% co-financed by PRIA)

- ozoniser (39% co-financed by PRIA)

- different small tools

- paperwork/licenses

- operating capital

Important but not initially mission critical (~60'000 EUR)

- do/co2 analyser and beer analyser

- additional set of tanks (39% co-financed by PRIA)

- bottling line (large bottles)

Good to have, but not strictly essential (~10'000 EUR)

- vacuum packer

- chest freezers

- yeast propagation tanks

Note: All PRIA bridge loans are provided by our current pre-crowdfunding shareholders.

Obligations to Investors, Profit Distribution

At Vaat we believe that sustainability doesn’t stop with the planet and its resources. Sustainable relationships with different stakeholder groups are just as important for creating a future proof business.

As a shareholder of Vaat you’re part of a community of people with a broad array of professional experiences, networks and skills. As a Vaat shareholder you’re an appreciated consultant, you’re given the opportunity to observe the day-to-day successes and failures of the company closely and you’re welcome to participate in the strategic and operational business when opportunity presents itself.

Benefits for Shareholders

- Be part of an amazing group of people.

-

Extend your network.

-

Get early access to limited edition beers.

-

Profit from discounts on all products (see below).

-

Participate in joint events like shareholder brews or join for collaboration brews with other breweries.

-

If you are so inclined, maybe there's even a possibility for you to participate in the strategic or even the day to day management of the company in some form or another.

Profit opportunities

We don’t really like to think about exit strategies just yet. We’re in the mindset of building something great, we’re in it for the long haul and we hope to take you along on that journey. But we understand you may want to know a bit more about how you can profit financially from investing in Vaat.

-

We are planning to start dividend payments in 2024. According to the current forecast, we plan to pay out 95'000 EUR in dividends in 2024.

-

Later funding rounds, e.g. in 2024 when we will likely prepare for our next growth phase, will provide an exit opportunity as well.

-

We are contemplating the possibility of introducing a secondary market module for our shareholders which would add the possibility for faster liquidity.

-

We currently should not and cannot think about selling the company. But we definitely want to do our job so well, that this can become an option in the future.

Additional Perks

We agree that you deserve perks! At the same time we don't think it's in the interest of a shareholder to see 5-10% of the invested money go into the production of perks. This is not how we understand lean management and our role as stewards of your money. We can't go for cheap, low quality merchandise either as that would not be Vaat... a) because low quality and b) because production of cheap merch is everything but sustainable. Also, this is an equity crowdfunding after all, not a perk based crowdfunding.

That said, here's what we want to give you in addition to a share of the company and everything described above.

EUR 180+

- 5% on drinks (e.g. at the tap room, brewery shop, friend sales, etc.)

- a 6-pack of fresh cans once production starts*

- plus, as soon as we can afford it, a quality Vaat T-Shirt, made from 100% recycled material.

EUR 990+

- 7% on drinks (e.g. at the tap room, brewery shop, friend sales, etc.)

- two 6-packs of fresh cans once production starts*

- plus, as soon as we can afford it, a quality Vaat T-Shirt, made from 100% recycled material

EUR 4950+

- 10% on drinks (e.g. at the tap room, brewery shop,friend sales, etc.)

- two 6-packs of fresh cans once production starts*

- a pack of 6 Vaat glasses*

- a quality Vaat T-Shirt, made from 100% recycled material

EUR 14'940+

- 15% on drinks (e.g. at the tap room, brewery shop, friend sales, etc.)

- three 6-packs of fresh cans once production starts*

- a pack of 6 Vaat glasses**

- a quality Vaat T-Shirt, made from 100% recycled material

EUR 29'970+

- 15% on drinks (e.g. at the tap room, brewery shop, friend sales, etc.)

- three 6-packs of fresh cans once production starts*

- a pack of 6 Vaat glasses**

- a quality Vaat T-Shirt, made from 100% recycled material

- you develop your own beer with us, we collaborate with you throughout the whole process from ingredients and style to naming and label.

* We’ll do our best to send you the beer for free. Nevertheless some shipping costs may apply. We may also define pick-up locations in areas with enough investors and find solutions for other areas. If you invest from outside of Europe, you may need to wait a bit longer for your beer.

** Info and warning: We already have these glasses and they have already paid for themselves. We're talking about great looking high quality Italian glassware with an equally great looking Vaat logo printed on them, which comes off after a while when the glasses are washed in the dishwasher with certain detergents. Hand or steam washing is no problem.

Risks and Mitigation

Competition

Risk

The beer industry is competitive. Big beer produces at very low cost, controls a lot of the distribution networks and controls ingredient markets. Among craft breweries competition is also increasing as more players are still joining the market and raising their quality as well as their production capacities.

Mitigation

As outlined in detail in our business plan, Vaat aims to brew top quality beer at competitive prices by leveraging technology that was previously not available to small producers. The projected growth of the craft sector is encouraging, there will be room for substantial growth for quality players for many years to come.

Last but not least our tap room will secure the necessary baseline.

Distribution

Risk

New players in the industry often find it hard to get their beers distributed in new markets. Every region has its own specific system of beverage distribution and culture around beer which can make entry into new markets hard. Oftentimes the large producers have a strong hold on many of the distribution channels.

Mitigation

Having our own Tap Room means we don't need to distribute a good proportion of the beer we produce.

Understanding different markets and the culture behind them is very important. Authentic long term relationships need to be built. We work towards good relationships with small to medium sized importers and distributors with an understanding and enthusiasm for great beer.

Technology

Risk

It can be quite safely assumed that it will still take a rather long time until advanced technologies in brewing will became available and affordable for micro breweries. The brewing industry is quite conservative when it comes to deviating from known and proven industry standards. Nevertheless some unexpected technological changes could accelerate that process earlier than expected.

Mitigation

We aim to step ahead of anything any small brewery has ever done in terms of cutting edge technology. We will not just use new technologies so far reserved for large breweries, we are also developing our own solutions together with trusted engineering partners to make sure we're ahead of the curve and can become a beacon of innovation in the micro brewing industry.

Innovation

Risk

The degree of innovation we are targeting has huge potentials but of course also brings the risk of failing to function as expected.

Mitigation

Technology really is one of our big strengths and our current prototypes and models show great promise. Nevertheless we're planning the system in such a way that each innovation can temporarily be replaced with a more conventional fallback solution if this should be needed.

Supplies

Risk

Brewing supplies like hops go through phases of low availability which can have two impacts on a brewery. For one that a specific recipe cannot be brewed in time because of a lack of ingredient and secondly that price hikes of the supplies in question endanger the profitability of a certain product.

Mitigation

Fluctuating supply prices need to be factored into product pricing and important dependancies in the supply chain need to be managed with care. A typical example for this are hop contracts to ensure availability. In order to lower the hop needs in terms of quantity without sacrificing quality we aim for maximum efficiency in extraction techniques.

Policy

Risk

Every country (or region) has different policies and tax systems in place regarding the production, warehousing, labelling, and sales of alcoholic beverages. Unexpected changes, such as for example the massive excise tax hikes the Estonian government has carried out recently, can have a serious impact on the business in a specific market.

Mitigation

It is of the utmost importance to be familiar with the legal framework and taxation policies regarding beer in each target market and adjust pricing and sales strategies accordingly. Brewing non-alcoholic beverages will also reduce the policy risk.

Covid-19 risks & mitigations

The Covid-19 pandemic and all its short and long term ramifications will have an impact on almost every single business worldwide.

A pandemic like this can affect tap room sales due to social distancing rules or different types of lockdown regimes. As a consequence of counter-measures against the pandemic the local or global economy suffers and market dynamics can change.

Mastering the crisis

As we are in the building phase this year we are not under pressure to grow. This gives us an advantage compared to many others regarding the timing of the pandemic.

Our focus was and is on building our brewery and that process luckily slowed down only a little. We currently have about two months of delay compared to our original plan.

When sales numbers started falling due to the gastronomy closing down, we started delivering our beer directly to people’s homes. Within a couple of weeks our Swiss friend sales mailing list grew from 50 subscribers to 130. Thanks to the thirst and solidarity of our community, we managed to reach our minimum sales goals during the months of the pandemic.

Nevertheless we are very likely also going to feel the direct consequences of the crisis insofar as beer that should have been sold in the months of the pandemic is now expiring and a portion of it may have to be written off.

Planning for the future

A Covid-19 wave in 2021 or other future pandemic could limit the capacity of our planned tap room. We calculate that even with a turnover loss of 1/3 regarding the tap room we would still make it to 2024 and positive cash flow without tremendous trouble.

Nevertheless it is becoming very important for companies like ours to put everything in place for successful online sales. We have therefore started building an e-shop and are talking to potential fulfillment partners who have the know-how and infrastructure to handle large numbers of small e-shop orders and deliver them all across Europe.

During normal times, an e-shop can be a nice additional revenue stream. But more importantly it is a hedge against possible future lockdowns or similar situations.

Summary

Thanks to our community, the fact that we’re in a building phase instead of a growth phase, as well as the covid-related interest reduction for our MES loan, we are not as heavily affected as we expected. The opening of our new brewery will be delayed by 2-3 months (originally we planned to start with production in December 2020).

We think that our growth plans are still realistic, also in a post-covid economy and we’re working on making our business more robust by building out a well functioning e-fulfillment sales channel.